Capacitor-Related Initiatives Geared Toward the 5G Market

Author: Nichicon

1/23/2020

The next-generation high-speed communication standard 5G (fifth generation mobile communication system) market is slated to expand. Compared with the current 4G/LTE (fourth generation mobile communication system/Long Term Evolution) technology, 5G represents a significant leap forward that brings features such as high speed, high bandwidth, and a high number of terminal connections together. Consequently, the standard is expected to help realize new services (such as remote medical treatment by enabling transmissions of high-resolution images, and automated driving at level 3), with “local 5G” to serve as an infrastructure technology to support the Internet of Things (IoT). In 2019, 19 overseas countries rolled out 5G services, while Japan deployed pre-commercial 5G services. Japan is gearing up for a launch of 5G services timed to coincide with the 2020 Tokyo Olympics. [Figure 1]

Achieving wide-area coverage for the new 5G standard will require the installation of a larger number of base stations than for existing 4G/LTE networks. Base stations may have to be installed in downtown areas where space is limited or in locations that complicate maintenance. Various approaches are currently being considered to improve the reliability of 5G base stations and reduce maintenance, including miniaturization (high-density packaging) and fanless designs. As a result, components used in 5G base stations need to be smaller in size, capable of operating at high temperatures, and offer longer life spans. Below we present several capacitor-related initiatives undertaken by NICHICON for the 5G market.

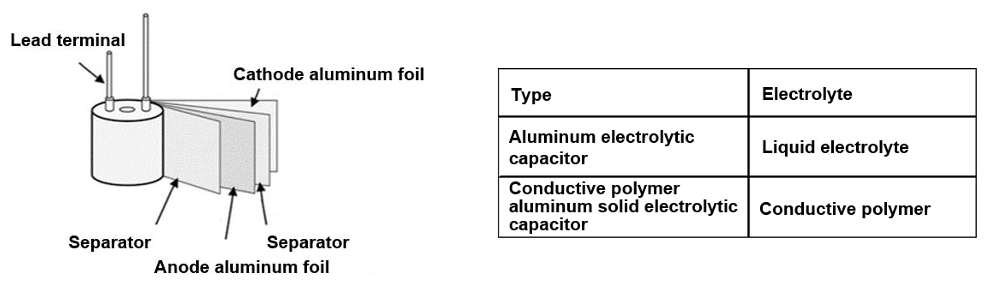

Conductive Polymer Aluminum Solid Electrolytic Capacitors

The following figure shows the element structure of a wound aluminum electrolytic capacitor and electrolytes by type of capacitor. Wound aluminum electrolytic capacitors retain the electrolyte in an element wrapped by anode foil and cathode foil with separator placed between the two foils. [Figure 2]

Conductive polymer aluminum solid electrolytic capacitors essentially have the same element structure as aluminum electrolytic capacitors. While aluminum electrolytic capacitors use a liquid electrolyte, conductive polymer aluminum solid electrolytic capacitors employ a solid electrolyte, which offers the following benefits and makes them ideal for 5G base stations.

(1) Low ESR

Conductive polymer aluminum solid electrolytic capacitors achieve electron conductivity through a conductive structure that uses PEDOT (conductive polymer) as the electrolyte. This results in conductivity that is roughly 10,000 times higher than that of an ion-conducting liquid electrolyte, allowing for an extremely low equivalent series resistance (ESR). The lower ESR raises the ripple current absorption effect in a circuit, reduces temperature increases by suppressing Joule heat accompanying current charges and discharges, and improves the maximum allowed ripple current of the product.

(2) Thermal characteristics

The ionic conductivity of liquid electrolytes is affected by changes in their viscosity and varies greatly by temperature. PEDOT, on the other hand, exhibits the electron conductivity of a metal. In terms of thermal properties, this means that low temperatures only result in a marginal increase in resistance. Because conductive polymer aluminum solid electrolytic capacitors are only minimally affected by product temperature, they can operate in a wide range of temperatures and remain stable.

(3) Long life span

Conductive polymer aluminum solid electrolytic capacitors do not exhibit changes in properties due to electrolyte evaporation that invariably occurs in capacitors with liquid electrolytes. Depending on their product design specifications and usage environment, they can offer a maintenance-free life span.

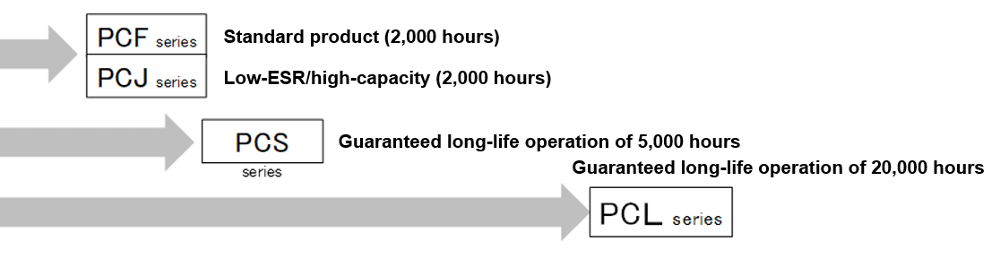

Addressing demand for long-life capacitors

In response to demand for longer life spans of capacitors to reduce maintenance frequency of base stations, NICHICON has started mass production of its PCL Series of chip-type 2 conductive polymer aluminum solid electrolytic capacitors, which offers industry-leading life span (guaranteed for 20,000 hours of operation at 105 °C). [Image 1]

.png)

[Image 1] PCL Series of chip-type conductive polymer aluminum solid electrolytic capacitors offers long life span and high reliability

The PCL Series offers four times the life span of the existing PCS Series (guaranteed for 5,000 hours of operation at 105 °C), and is expected to contribute to the realization of maintenance-free base stations. Its specifications are dimensions:φ5 × 6L to φ10 × 12.7L (mm), temperature range: -55 °C to 125 °C, rated voltage range: 4 V to 25 V, and rated capacitance range: 12μF to 2,700 μF. [Figure 3]

[Figure 3] Life span comparison: Existing series of 105 °C products vs. PCL Series

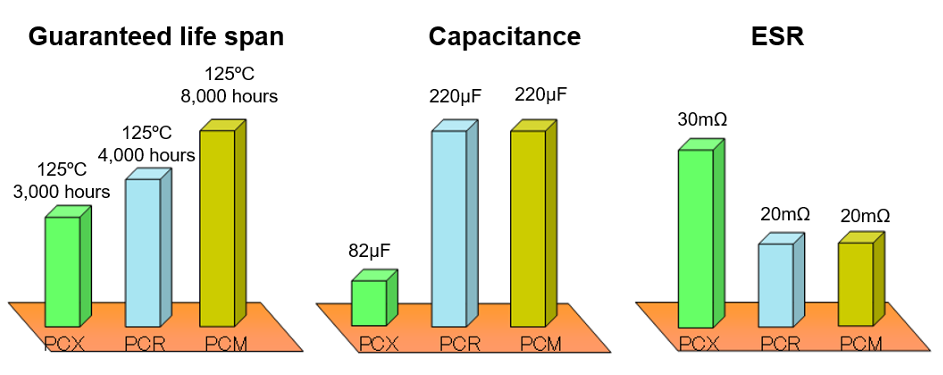

Addressing demand for high-voltage capacitors

The characteristics of 5G networks—high communication speed, high bandwidth, and high number of terminal connections—increases power requirements. From the perspective of energy efficiency, demand is increasing for components that can operate at voltages of 50-80 V. NICHICON strengthened its product lineup with the addition of its PCM Series, which supports higher voltages and offers industry-leading life span (guaranteed for 8,000 hours of operation at 125 °C). [Image 2]

[Image 2] PCM Series of chip-type conductive polymer aluminum solid electrolytic capacitors is guaranteed for operation at 125 °C and offers industry-leading life span

The PCM series maintains the capacitance, ESR, and other features of the existing PCR Series (guaranteed for 4,000 hours of operation at 125 °C), but achieves twice the life span. Its specifications are dimensions: φ6.3 × 6L to φ10 × 12.7L (mm), temperature range: -55 °C to 125 °C, rated voltage range: 16 to 80V, and rated capacitance range: 12 μF to 1,000 μF. [Figure 4]

[Figure 4] Performance comparison: Existing series of 125°C products vs. PCM Series

(rated voltage: 25V, size: φ8 × 10L)

Conductive Polymer Hybrid Aluminum Electrolytic Capacitors

Conductive polymer hybrid aluminum electrolytic capacitors employ conductive polymer and liquid electrolyte as the electrolyte, and achieve low ESR performance through the application of a proprietary conductive polymer forming technology. By developing a liquid electrolyte optimized for use with conductive polymer, these capacitors provide low-leakage current performance—a characteristic of liquid electrolytes—without hurting performance of the conductive polymer. NICHICON aims to strengthen its product lineup in response to demand for products that can operate at high temperatures and have longer life spans.

[Addressing demand for high-temperature capacitors]

NICHICON has launched its GYA Series (guaranteed for 4,000 hours of operation at 125 °C) and its long-life GYB Series (guaranteed for 10,000 hours of operation at 105 °C). In 2019, it started production of its GYC Series (guaranteed for 4,000 hours of operation at 135 °C; 2,000 hours of operation for φ6.3 size), which can operate in high temperatures. [Image 3]

[Image 3] GYC Series of conductive polymer hybrid aluminum electrolytic capacitors

The GYC Series improves the conductive polymer forming technology developed for the GYA Series, and employs a material that is less susceptible to evaporation when exposed to high temperatures than the liquid electrolyte used in the GYA Series. As a result, it offers industry-leading guaranteed operation of 4,000 hours at 135 °C (2,000 hours of operation for φ6.3 size).

Another characteristic of the GYC Series is that it specifies rated ripple current values for both 125 °C and 135 °C, allowing guaranteed operation to be selected in function of the application. For example, if using the GYC Series in a 125 °C environment, the rated ripple current value increases up to 1.8x compared with usage in a 135 °C environment. As a result, the GYC Series also addresses demand for capacitors with high rated ripple current. [Figure 5]

[Figure 5] Rated ripple current comparison (GYA Series vs. GYC Series)

Chip-type Aluminum Electrolytic Capacitors

Due to the power-supply voltage requirements of 5G base stations, demand for components with a rated voltage of 50-80 V is increasing. NICHICON aims to expand the rated voltage of its chip-type aluminum electrolytic capacitors to meet this demand.

[Addressing demand for high-voltage capacitors]

NICHICON developed the UCH Series (guaranteed for 2,000 hours of operation at 125 °C) as a product line that can reliably operate in high temperatures, and started production in 2015. [Image 4] When used for prolonged periods, aluminum electrolytic capacitors generally tend to see an increase in product ESR due to evaporation of the liquid electrolyte, raising concerns over increased power usage in the devices. The UCH Series employs a low-evaporation, low-resistance liquid electrolyte that greatly suppresses ESR deterioration over time. In addition, because it is one case size smaller than the existing UCZ Series, the UCH Series can contribute to miniaturization, improved energy efficiency, and longer life spans of devices. The series is limited to rated voltages of 25 V and 35 V, but NICHICON plans to expand to rated voltages of 50 V and 63 V.

[Image 4] UCH Series of chip-type aluminum electrolytic capacitors

Large Can-type Aluminum Electrolytic Capacitors

Large can-type aluminum electrolytic capacitors that smooth power input require a high degree of reliability. Demand for components with longer life spans, in particular, has increased from the standpoint of reducing maintenance costs. Accordingly, NICHICON has developed the industry-leading LGZ Series of snap-in terminal-type aluminum electrolytic capacitors (guaranteed for 20,000 hours of operation at 105 °C). [Image 5]

[Image 5] LGZ Series of snap-in terminal-type aluminum electrolytic capacitors offers industry-leading life span

By combining highly reliable electrode foil and electrolyte paper with a high amount of liquid electrolyte, the LGZ Series maintains the same dimensions as the existing LGR Series (guaranteed for 10,000 hours of operation at 105 °C), but achieves twice the life span. It provides ideal aluminum electrolytic capacitors for circuit designs that aim to increase life span. [Figure 6]

Durability Performance (at 105 °C)

[Figure 6] Comparison of life span (LGR Series vs. LGZ Series)

The next-generation high-speed communication standard 5G is a technology that will be utilized in a broad range of fields. This means additional performance gains will be expected from base station components going forward. NICHICON plans to continue developing new products that meet and anticipate future market needs.