Large Can Aluminum Electrolytic Capacitors

Author: Nichicon

7/31/2015

.jpg?lang=en-US)

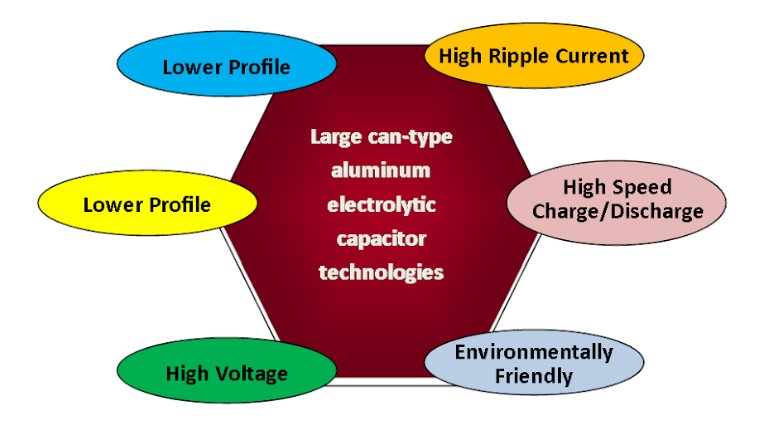

[Figure 1] Characteristics of large can-type aluminum electrolytic capacitors

The market for large can-type aluminum electrolytic capacitors can be categorized into the following primary areas: household appliances, industrial inverters, transportation (e.g. rail car applications), energy, medical equipment, and communications. The characteristics that are required for large can-type aluminum electrolytic capacitors are: 1) lower profiles, 2) high ripple current, 3) high voltage, and 4) high-speed charge-discharge.-

Lower Profile

As electronic modules become smaller and available space is reduced, the demand for low-profile, large can-type aluminum electrolytic capacitors grows. The key to developing lower-profile products lies in using leading-edge etching technology to increase the effective surface area of the electrode foil, raise the capacitance per unit area and reduce the amount of foil surface used, thereby making products smaller. In addition, by revising the fiber structure of the electrolytic paper Nichicon is able to use thinner paper and still improve the withstanding voltage, thus increasing the capacitance. By combining the new etching, electrolytic paper developments capacitor size reduction is achieved. -

High Ripple Current

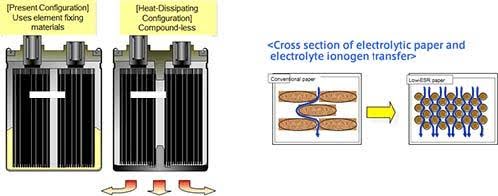

As performance requirements increase, the current load increases, requiring large can aluminum electrolytic capacitors capable of withstanding high ripple current. The internal structure is one of the most important factors in developing high ripple current products. Materials such as thermoplastic resin are often used to hold the elements of conventional screw terminal aluminum electrolytic capacitors. Nichicon has developed a rib configuration that holds the elements without the use of resin compounds thereby achieving a much higher rate of heat dissipation. The temperature rise of the element due to ripple current is reduced. Conventional capacitors use electrolytic paper with a relatively large fiber diameter. However, Nichicon’s low-density electrolytic paper, with a small fiber diameter allows lower ESR and lowers the amount of heat generated.

Technology needed to achieve high ripple current.

-

High Voltage

The industrial market place demand for high voltage large can-type aluminum electrolytic capacitors is growing due to advances being made in efficiencies and energy-saving applications. One of the keys to the development of a high-voltage product is the advances made in highly reliable electrode foil. Nichicon is working with chemical manufacturers to develop a new electrolyte that is resistant to thermal decomposition (heat resistant) and will offer a higher withstand voltage. -

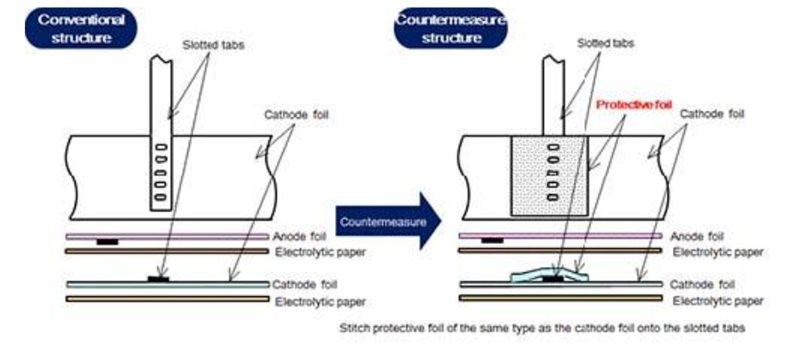

High-Speed Charge-Discharge

The increasing speed and performance of products using general-purpose inverters and motor controls generate steep voltage variations. During charge and discharge (particularly discharge), the electrolytes are subjected to localized stresses that can reduce their withstanding voltage and may, ultimately, lead to short-circuit. For this reason, repeated charging and discharging of large can-type aluminum electrolytic capacitors with large differences in electric potential is known to reduce the electrolyte withstanding voltage at the lead tab of the cathode foil. Using Nichicon’s patented technology, a protective foil structure [Figure 3] dramatically reduces this potential.

As the power electronics industry adopts inverters, and the loads for the many different types of power sources and motor controls become progressively more severe, this new technology is increasingly important. Developing highly reliable applications is vital to the industry.

New Product Development to Meet Market Needs

-

Ultra-miniature type snap-in terminal aluminum electrolytic capacitors

Nichicon is developing an ultra-miniature (type of snap-in terminal and type of aluminum) capacitor guaranteed to 105 °C. That is smaller than Nichicon’s smallest series, the LGL. Key in the development of this smaller-sized series is the development of; high capacitance, highly reliable electrode foil and the use of thinner electrolytic paper. The new product will be more than 20% smaller than the LGL series, making it the smallest in the industry. When the size of a 450 V/560 µF, LGL series is compared to the new series with the same capacitance and voltage one can see the size improvement. The LGL is φ35×40L, whereas the new product is φ35×35L.

Size comparison of Nichicon series

Size comparison of Nichicon series -

600 V-rated snap-in terminal type aluminum capacitor

The LGN and LGX series are Nichicon’s highest rated snap-in terminal type aluminum capacitors and are guaranteed to 105 °C with a maximum voltage of 500 V. Nichicon is developing a new product that is guaranteed to 105 °C with a maximum rated voltage of 600 V. The core technologies needed in the development of this new product includes the use of a high reliability electrode foil with high withstanding voltage as well as the use of a high withstanding voltage electrolyte (high-heat resistivity). -

LNU miniature high-ripple screw terminal type aluminum electrolytic capacitors

The LNU is a reduced size, high-ripple, screw terminal type aluminum electrolytic capacitor guaranteed to 105 °C. Key in the development of this series are: (1) the use of electrode foil with high withstanding voltage oxide film, (2) long-term stability, incorporating an electrolyte solution with enhanced film restoring capacity at high voltages, (3) use of low-density electrolytic paper with high withstanding voltage and, (4) an enhanced heat dissipation structure that results in a higher voltage (rated voltage: 525V) and longer life (guaranteed to 5,000 hours) over the standard screw terminal series, LNT. The LNU is approximately 20-30% smaller than other products rated at 500 V; which contributes to module size and weight reductions. Furthermore, the LNU series employs Nichicon’s high-speed charge-discharge technology, which has earned high marks for applications in industrial equipment where load changes are severe. This product is ideal for use in motor controls and other equipment involving repeated quick charge and discharge in short periods of time.

The primary use for aluminum electrolytic capacitors is expected to continue to be for smoothing power sources, particularly in power electronics applications. The ongoing developments in next-generation power semiconductors are generating demand for high heat resistance, high voltage, and low ESR; all in smaller package sizes. The Nichicon Group’s development teams are working on new materials, including electrode foils and electrolytes. Nichicon will continue to develop new products in response to market needs and proposing products that will satisfy our customers.