Latest Technological Trends in Conductive Polymer Aluminum Solid Electrolytic Capacitors

Author: Nichicon

2/28/2019

Introduction

It has been more than 30 years since the introduction of the conductive polymer poly ethylenedioxythiophene (PEDOT) with its high heat resistance and electrical conductivity was used in capacitors as a solid electrolyte. The market for conductive polymer capacitors has expanded substantially, driven mainly by personal computers and home video game consoles. It continues to expand amid increasingly diversified needs. NICHICON is developing products to meet these increasingly diversified needs.

Wound-type Conductive Polymer Aluminum Solid Electrolytic Capacitors

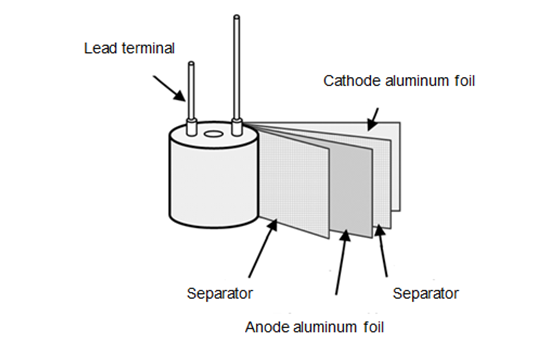

Figure 1 shows the structure of a standard aluminum electrolytic capacitor. The anode foil and the cathode foil with the electrolyte separating the foils. Both the conductive polymer and the electrolytic solutions have the same basic structure, but differ in terms of their performance. The use of a solid electrolyte compared to a liquid electrolyte offers the following benefits.

-

Low ESR

PEDOT conductivity is, about 10,000 times higher compared with electrolytic solutions in which ion transfer is used for conductivity. Thus, ESR can be substantially reduced. Furthermore, by lowering the ESR of the product, the temperature rise is also reduced, leading to an increase in the allowable ripple current.

-

Thermal property

Solid electrolyte PEDOT features metallic electronic conduction and its thermal property is such that resistance increases slightly on the low-temperature side. Thus, temperature dependence is small, demonstrating stability over a wide range of temperatures.

-

Long life

Solid electrolytic capacitors, do not experience the “dry-up phenomenon” compared to the electrolytic solution used by the electrolyte type capacitor. Depending on the products design and usage, it is expected the capacitors will have a service life that is nearly maintenance free.

Market Trends

In recent years, advances in car electronics technologies and the rise of electric and hybrid vehicles (EV/HV) has led to an increase in the number of electronic control units (ECU) and a growing demand for electronic components installed in automobiles. The market for heat-resistant aluminum electrolytic capacitors for automotive applications is particularly robust. Up to now, automotive electronic circuits have been installed in the passenger cabin, but recently it has become commonplace to move them into the engine compartment (integrated with electronic machinery). High reliability in the form of high heat resistance, high ripple current and high withstand voltage is required to save energy and ensure the long life of automobile driving system ECUs.

Markets in which high reliability is required is not limited to the automotive field. With the expansion of fixed broadband access and mobile communication services, network environments are becoming increasingly sophisticated and advanced. Telecommunications infrastructure supporting these services are advancing throughout the world. As base station units become increasingly miniaturized, The parts used must also be miniaturized, while maintaining compatibility with the higher temperatures inside the housings. In addition to miniaturization, frequent maintenance is difficult, thus the demand for long life capacitors is on the rise.

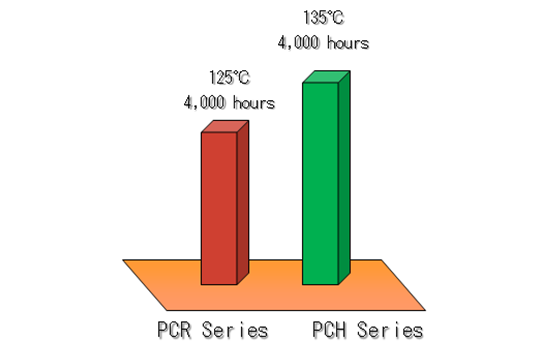

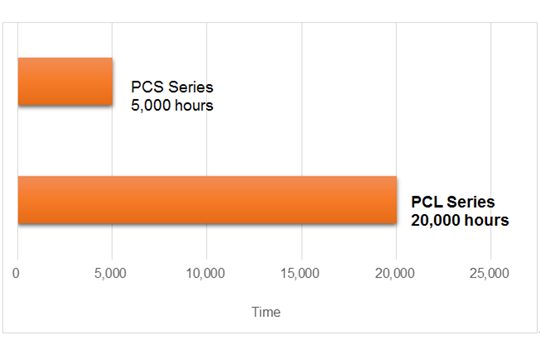

The PCH and PCL Series

As already mentioned, there is a growing need for smaller-sized aluminum electrolytic capacitors able to withstand higher temperatures and higher voltages than ever before. To meet a wide range of demands in automotive applications, industrial machinery, telecommunications base stations, medical equipment and consumer devices, NICHICON has launched the PCH Series (Figure 2) of conductive polymer aluminum solid electrolytic capacitors with the world’s highest temperature of 135 °C. The PCL Series (Figure 3) of conductive polymer aluminum solid electrolytic capacitors, has the highest standard for endurance guaranteed to 20,000 hours at 105 °C. The PCH and PCL Series specifications are as follows.

The PCH Series has product dimensions of φ8×7L mm to φ10×12.7L mm, rated voltage range of 25 V to 63V, a rated capacitance range of 22 μF to 470 μF and a temperature range of -55 °C to 135 °C. The ripple current range is 700 mARMS to 2,200 mARMS (at 135 °C, 100 kHz) with an endurance life guaranteed to 4,000 hours at 135 °C. This is 10 °C higher than the 125 °C guaranteed endurance life of the current PCR Series (Figure 4).

The PCL Series has product dimensions of φ5×6L mm to φ10×12.7L mm, a rated voltage range of 4 V to 16 V DC, a rated capacitance range of 22 μF to 2,700 μF and a temperature range of -55

°C to 105 °C. The ripple current range is 1,000 mARMS to 5,600 mARMS (at 105 °C, 100 kHz) with an endurance life guaranteed to 20,000 hours at 105 °C. 20,000 hours is four times longer life than the current guaranteed 5,000 hours of the PCS Series (Figure 5).

The PCH Series offers the world’s highest category temperature guaranteed to 135 °C, while the PCH Series has the highest standard for endurance. These products have optimized manufacturing processes and materials.

Going forward, the market is expected to continue expanding amid growing demand for conductive polymer aluminum solid electrolytic capacitors. Demand has been particularly steady in the automobile market, where electronic equipment and advanced functionality has been accelerating due to the spread of self-driving vehicles. Focused on these technological trends, NICHICON has already initiated the development of high heat resistance, high withstand voltage and high-capacity conductive polymer aluminum solid electrolytic capacitors. Nichicon is developing high-temperature products and expanded ratings in existing series including conductive polymers higher capacitances will be achieved by using thinner materials and adopting the use of high-capacity foil.

The new product lineups and expanded ratings and sizes are available in both in Japan and overseas.

Figure 1: Wound-type conductive polymer aluminum solid electrolytic capacitor structure

Figure 2: PCH Series

Figure 3: PCL Series

Figure 4: Endurance guarantee comparison with PCH Series

Figure 5: PCL Series guaranteed life comparison