Latest Technological Trends in Onboard Automotive Aluminum Electrolytic Capacitors

Author: Nichicon

10/3/2019

The automotive and onboard automotive industries are characterized by the development of vehicles with self-driving and safely features such as advanced driver assistance systems (ADAS). Such innovation is prompting demand for higher-performance components, mainly for the sensors they require. Progress in space-saving onboard automotive equipment is accelerating demand for miniaturized, high-capacitance, and low-ESR automotive grade capacitors, as well as for components that can withstand harsh, extremely hot environments.

Below, we outline the latest technological trends for such capacitors, including aluminum electrolytic capacitors, conductive polymer aluminum solid electrolytic capacitors, and conductive polymer hybrid aluminum electrolytic capacitors.

UCM Series (Aluminum Electrolytic Capacitors)

NICHICON has expanded the UCM series of aluminum electrolytic capacitors, which offer better space savings and higher performance in automotive and onboard automotive devices, by adding capacitors with diameters of φ12.5 mm to φ18 mm [Fig. 1]. In addition to having the high capacitance needed to serve as backup power sources in onboard automotive devices, demand calls for capacitors that are smaller and have higher ripple tolerance. We have optimized the capacitor structure by employing high-capacitance electrode foils and thinner electrolytic paper to achieve an optimal combination of materials, achieving approximately 1.9 times the capacitance and 2.1 times the rated ripple current of capacitors of the same size in our existing UCD series (105 °C chip-type) [Table 1].

| Rated Voltage (V) | Case Size φDxL(mm) |

Capacitance (μF) | Rated ripple current (mArms) | ||||

| UCD series (current) |

UCM series (new) |

Change | UCD series (current) |

UCM series (new) |

Change | ||

| 35 | 12.5x13.5 | 680 | 910 | x1.3 | 1100 | 1420 | x1.3 |

| 16x16.5 | 1000 | 1800 | x1.8 | 1800 | 1910 | x1.1 | |

| 63 | 12.5x13.5 | 220 | 360 | x1.6 | 800 | 1250 | x1.6 |

| 16x16.5 | 470 | 620 | x1.3 | 1410 | 1740 | x1.2 | |

| 100 | 12.5x13.5 | 68 | 130 | x1.9 | 500 | 1050 | x2.1 |

| 16x16.5 | 150 | 240 | x1.6 | 793 | 1500 | x1.9 | |

[Table 1] Comparison of the electrical properties of capacitors of the same size

.png)

[Fig. 1] New φ12.5 mm to φ18 mm range of UCM series chip-type aluminum electrolytic capacitors

PCZ/PCH Series (Conductive Polymer Aluminum Solid Electrolytic Capacitors)

NICHICON launched the PCZ series [Fig. 2] (rated for 2,000 hours at 150 °C) in April to meet the demand for high dependability in high-temperature environments. As a result, we can offer capacitors with low ESR even in extremely high-temperature environments, temperatures conductive polymer aluminum solid electrolytic capacitors were not previously capable of handling. We achieved a 2,000-hour life at 150 °C while maintaining the characteristic low ESR and high ripple tolerance of conductive polymer aluminum solid electrolytic capacitors. To do so, we optimized materials constituting the conductive polymer and improved the self-healing features of aluminum oxide films, as well as refining the sealing technology. The lineup includes capacitors with rated voltage ranging from 25 V to 35V DC, capacitance from 100 μF to 330 μF, and product dimensions from φ8x10L to φ10x12.7L (mm).

Mounting powertrain ECUs in the engine compartment is growing increasingly common, boosting demand for smaller heat-resistant capacitors in a broader range of voltages. In response, we are expanding our PCH series lineup [Fig. 3] (4,000 hours guaranteed at 135 °C), which is one of the best in the industry for automobile applications. Employing new technology, we have developed new capacitors with voltage ratings of 16 V, 20 V, and 80 V, and added a φ6.3 mm size, expanding the potential area of application for the 135 °C series through further optimization. As a result, we can provide customers with capacitors that fit their specific needs, even in high-temperature environments without losing the low ESR and high ripple tolerance characteristic of conductive polymer aluminum solid electrolytic capacitors.

[Fig. 2] PCZ series chip-type conductive polymer aluminum solid electrolytic capacitors (highest heat resistance in the industry at 150 °C)

[Fig. 3] PCH series chip-type conductive polymer aluminum solid electrolytic capacitors (guaranteed up to 135 °C)

GYA Series (Conductive Polymer Hybrid Aluminum Electrolytic Capacitors)

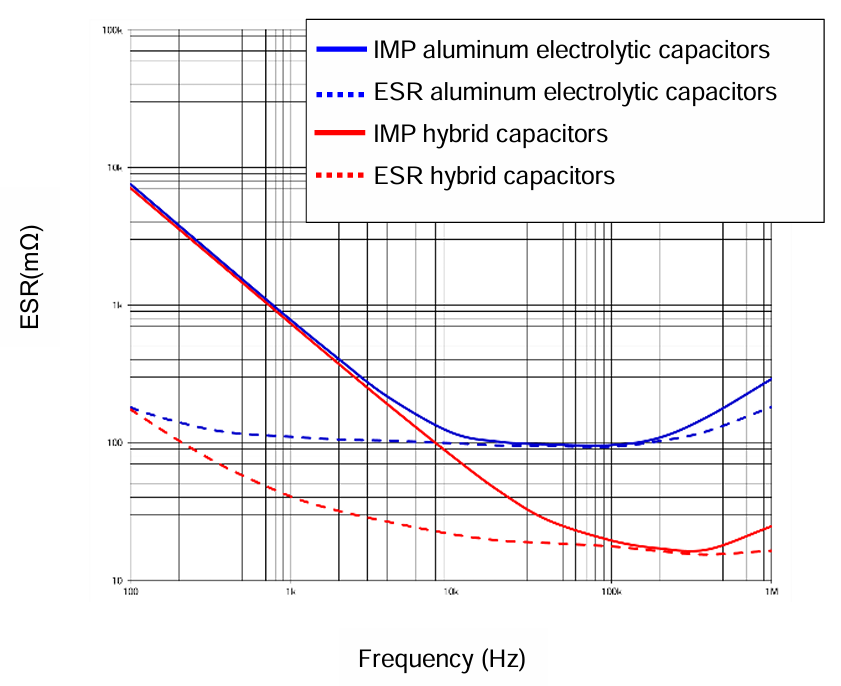

Demand is increasing for onboard automotive electronic control units (ECUs) featuring even higher heat tolerance, low resistance, and high ripple tolerance. NICHICON responded by developing the GYA series [Fig. 4] (rated up to 125 °C), which it began mass producing in 2017. Conductive polymer hybrid aluminum electrolytic capacitors utilize hybrid electrolytes obtained by fusing conductive polymer and electrolytic solution and applying proprietary conductive polymer formation technologies to achieve low ESR. By virtue of its electrical conductivity, the resulting conductive polymer experiences minimal reductions in performance when subjected to high frequencies or low temperatures. This contributes to higher performance in electronic devices [Fig. 5]. Developing electrolyte solutions tailored to the conductive polymer enables realization of the solution’s properties, such as low leakage current, without losing the characteristics of the conductive polymer. A further advantage of using conductive polymer, is its’ stability at in high-temperature environments which helps extend capacitor lives.

The GYA series comes in sizes ranging from φ6.3x5.8L mm to φ10x10L mm, voltage ratings ranging from 16 to 63V, and capacitance ranging from 10 to 470μF. The GYA series has a temperature range of -55 °C to 125 °C, rated ripple current from 700 to 2,100 mARMS (at 125 °C, 100 kHz), and a rated life of 4,000 hours at 125 °C (with superimposed ripple). The φ8x10L mm and φ10x10L mm sizes have an anti-vibration structure (guaranteed up to 30 G).

Anticipating greater demand for conductive polymer hybrid aluminum electrolytic capacitors, we are working to improve their heat resistance and capacitance. We expect to develop capacitors guaranteed at 135 °C by utilizing the conductive polymer film deposition technology obtained through the development of the GYA series to develop an electrolyte that is resistant to evaporation even in high-temperature environments. We will improve capacitance by employing thinner materials and high-capacitance foils. We plan to expand our lineup and size ranges to meet broad-ranging private-sector demand, including home electronics, telecoms equipment, and industrial machinery.

[Fig. 4] GYA series chip-type conductive polymer hybrid aluminum electrolytic capacitors

[Fig. 5] Frequency and temperature in conductive polymer hybrid aluminum electrolytic capacitors

NICHICON offers an extensive lineup of aluminum electrolytic capacitors with a variety of characteristics to meet its customers’ requirements. NICHICON will develop new and custom products that meet the most demanding requirements.