Hybrids vs Polymers vs Aluminums

Author: Mark Gebbia

3/19/2018

Aluminum electrolytic, aluminum polymers, and hybrid polymers all have advantages and disadvantages when comparing each one. Designers need to be aware of these differences when determining which capacitor type is best suited for use in their application.

The most notable difference between aluminum electrolytics and polymers is their electrolyte. Aluminum electrolytics have a liquid electrolyte while polymers have a solid electrolyte. These differences play a major role in the characteristics of each type of capacitor.

The solid polymer electrolyte gives the polymer capacitors advantageous characteristics over liquid aluminum electrolytic capacitors, among them are:

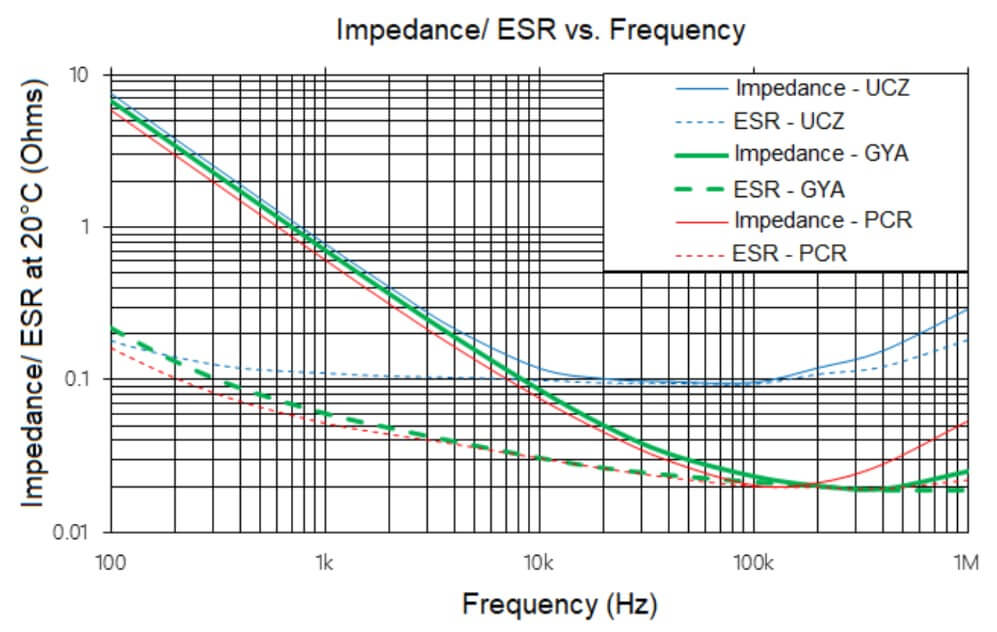

- Lower ESR at high frequency

- Lower D.F. / tan δ at lower frequencies

- Higher ripple current ratings

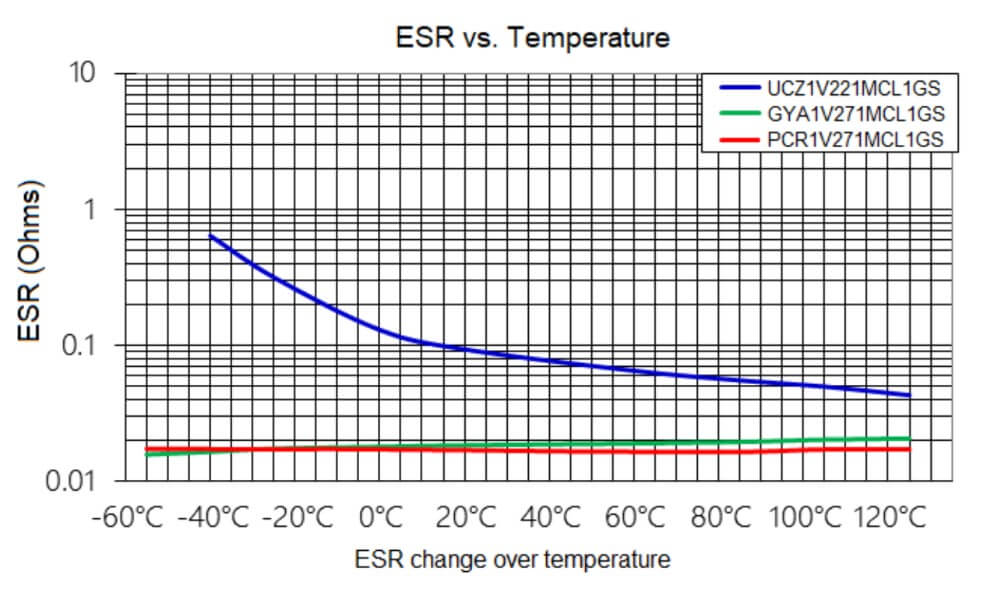

- Stability over temperature

- Wider operating frequency range

- Long life – 10X for every 20 °C reduction

The advantages are as follows:

- Lower ESR at high frequency – allows the capacitors to tolerate higher ripple currents without heating up, as well as the use of smaller capacitance values.

- Lower D.F. / tan δ – this translates into lower ESR values, and allows the capacitor to run cooler.

- Higher ripple current ratings – allows the use of fewer capacitors and lower total capacitance in applications where large ripple currents are present. Polymer ripple currents are up to 6 times higher than electrolytic capacitors.

- Stability over temperature – capacitance stays very close to its initial 25 °C value, compared to aluminum electrolytics where the capacitance can change up to 30% over its temperature range.

- Wider operating frequency range – allows polymers to be used at frequencies up to 500 kHz compared to aluminum electrolytics 100 kHz maximum frequency.

- Long life – polymer capacitors expected life increases 10 times for every 20 °C decrease where aluminum electrolytics would only increase by a factor of 4 over the same temperature decrease.

Although the advantages of polymers are significant, they do possess disadvantages when compared to aluminum electrolytic capacitors:

- Higher cost – polymers can cost over twice the amount for the same capacitance and voltage value.

- Higher leakage currents – polymers can have up to 3 times higher leakage current

- Lower surge voltages – polymers surge voltage is typically only 15% above their rated voltage compared to electrolytics at 25%.

- Limited voltage range – polymers can only withstand up to 125 V DC, while electrolytics can go as high as 630 V DC (700 V DC will be introduced soon.)

- Inconsistent self‐healing – polymer should be able to self‐heal but since they have a solid electrolyte, they can become short circuits.

- Low resistance to humidity – moisture penetrating into the capacitor body can cause the capacitor to fail as a short circuit.

The inconsistent self‐healing ability prevents polymer capacitors from use in some applications such as automotive.

Hybrid polymer capacitors are manufactured just like a polymer capacitor except there are additional processing steps of adding a liquid electrolyte to the polymer electrolyte material. Hybrid capacitors, as the name suggests, end up with a solid and liquid electrolyte instead of a single liquid or solid electrolyte.

As a result of the solid and liquid electrolyte combination hybrid capacitors have many advantageous characteristics of both liquid and solid electrolytic capacitors. Those advantages include:

- Low ESR at high frequencies – similar to polymers.

- Stability over temperature – similar to polymers.

- Stability over frequency – similar to polymers.

- Wide operating frequency – up to 500 kHz, similar to polymers.

- Low leakage currents – 1/3 the leakage of a polymer, similar to aluminum electrolytics.

- High humidity resistance – similar to aluminum electrolytics.

- Consistent self‐healing – just like aluminum electrolytics.

- Lower cost compared to a polymer capacitor – as much as 40% the cost of a polymer.

- Failure mode is open circuit.

There is one important significant difference between polymers and hybrid polymers. The expected life at different temperatures for hybrids is calculated the same way as aluminum electrolytic capacitors are their life expectancies only double for every 10 °C decrease instead of 10 times increase for every 20 °C decrease that polymers have.

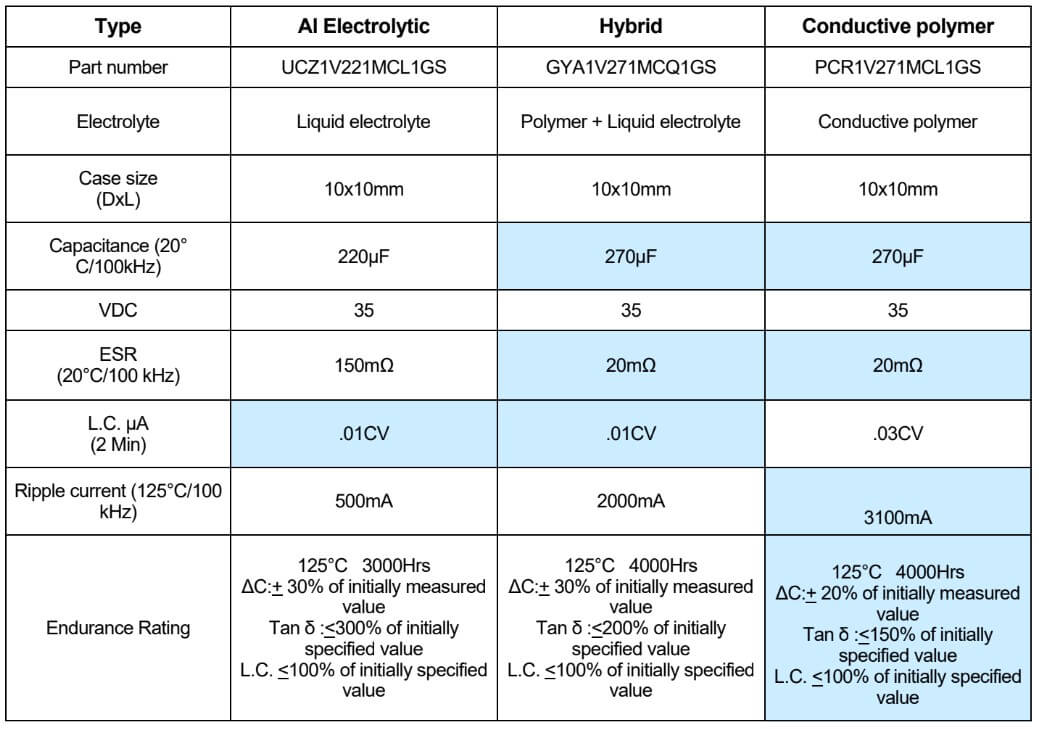

A comparison between the different types of capacitors is shown below. Any advantage is highlighted in blue.

Comparison of Capacitors