New Li‐Ion Rechargeable Battery in Capacitor Form Factor

Author: Nichicon

4/20/2020

Fixtureless circuit board mountable Li‐ion rechargeable batteries

Li‐ion batteries that are a Li‐ion battery and EDLC in one!

Nichicon has a new Li‐ion rechargeable battery that can be directly mounted onto circuit boards without any special fixtures. This new product line is called the SLB series. This new SLB series has some of the characteristics of both rechargeable Li‐ion batteries and EDLC’s making it a viable alternative in applications using either EDLCs or rechargeable batteries. In addition the long lead configuration makes it easy to board mount.

Through the use of proprietary materials and processes Nichicon was able to give the SLB its unique properties that no other battery can match.

The SLB has capacities starting at 0.35 mAh in case sizes as small as 3 mm x 7 mm.

Utilizing the same case style as an aluminum electrolytic capacitor gives the SLB series one of its more unique properties. The 3 mm x 7 mm case size is the smallest size of any Li‐ion rechargeable battery available today. This makes the SLB perfect for applications where space is at a premium.

The SLB has excellent electrical features including a maximum voltage of 2.8 V. This is greater than an EDLC. It has an energy density that is nearly 8 times greater than EDLC’s. Compared to LI‐ion batteries the SLB has a power density 3 times greater, a wider operating temperature range and can be discharged up to 20,000 times where a Li‐ion battery can only withstand a few thousand cycles. The SLB will not ignite if damaged making it a much safer product compared to Li‐ion batteries.

The SLB can be charged and discharged in as short as 3 minutes repeatedly. Discharge times this short are superior to Li‐ion batteries and approach the capabilities of EDLCs giving then the opportunity to be viable substitutes in applications where EDLCs are utilized.

The advantageous characteristics of the SLB are attributed to the electrodes used to manufacture the batteries. Traditional Li‐ion batteries use graphite as the anode where the SLB uses lithium titanate. The lithium titanate used in the anode was developed by Toshiba Corporation and is utilized in Toshiba’s SCiB™ rechargeable batteries. Nichicon has licensed this technology. The Toshiba technology along with Nichicon’s knowledge of capacitor manufacturing combines to produce the SLB series.

Energy is stored in the SLB batteries by use of an electrochemical storage mechanism that utilizes electrochemical reactions that transfer Lithium ions into the electrolyte and then into the anode. A current is generated and released into the circuit. The batteries capacity is achieved by the absorption and release of lithium ions in the electrodes.

Typical Li‐ion rechargeable batteries use electrolytes where lithium salts are dissolved in an organic solvent. When a specified voltage is applied the lithium ions leave the solvent and collect on the anode plate. The surface of the anode is coated with a solid electrolyte interphase (SEI) coating. When the lithium ions pass through the SEI the anode generates a significant resistance that increases as the SEI coating grows thicker. The reaction voltage needed for the electrolyte to decompose is extremely small at 0.1 V. This low of a decomposition voltage results in the formation of a thick SEI and a higher internal resistance. Using Lithium Titanate as the anode increases the reaction potential to 1.55 V. This enables the SEI coating to remain thin and reduces electrolyte decomposition. As a result of the lower internal resistance and reduced lithium ion consumption the SLB has a superior life. As an example we charged an EDLC to 2.7 V and stored it for 30 days at 25 °C. After 30 days the voltage dropped to 1.97 V, a voltage decrease of 27%. In comparison we took our 0.35 mAh SLB battery and charged it to 2.8 V and stored it at 60 °C for 40 days. The voltage after 40 days was at 2.53 V, a voltage decrease of only 9.64%.

Lithium titanate is stable with temperature resulting in low self‐discharge even at high temperatures.

Optimization of the electrodes, separator and electrolyte also gives the SLB superior temperature tolerance, cycle life and makes the SLB safe to use.

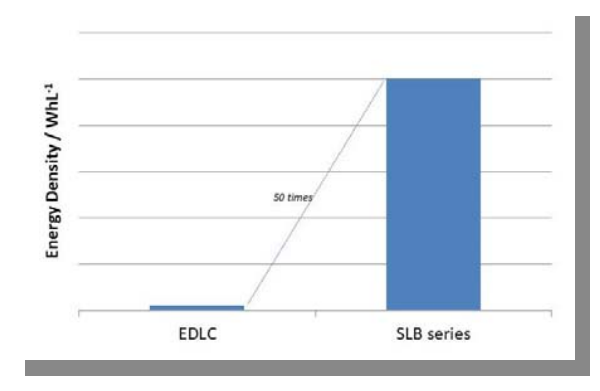

The SLB can store nearly 50 times the energy of an EDLC of the same size making it a viable alternative to EDLC’s and in applications where higher storage density is required. Applications like energy harvesting. See Figure 1 below.

Figure 1 – A comparison of the volume energy densities of Nichicon’s electric double layer capacitors (EDLC) vs its small li‐ion rechargeable batteries.

Compared to typical Li‐ion rechargeable batteries the SLB has superior rapid charge/ discharge characteristics. Li‐ion batteries typically take between 2 hours and 3 hours to charge where the SLB can be charged/discharged at a 20 C rate or in 3 minutes to 80% of a full charge. As a result of this ability the SLB can be utilized in high power applications and as an alternative to EDLCs.

At low temperatures the SLB has excellent characteristics. At temperatures below 0 °C Li‐ion batteries have difficulty as the lithium ions are less likely to be absorbed by the graphite anode. This causes the formation of Lithium metal dendrites. The dendrites can pass through the cathode and anode resulting in damage to the separator and can cause an internal short. If a short occurs the resulting high current generates heat. This results in the anode and electrolyte to have a reaction causing the electrolyte to decompose resulting in the cathode and electrolyte reacting together. Sparks from the short can cause the cathode’s crystalline structure to collapse resulting in a combustive reaction to take place. Repeated reactions can result in thermal runaway and a fire.

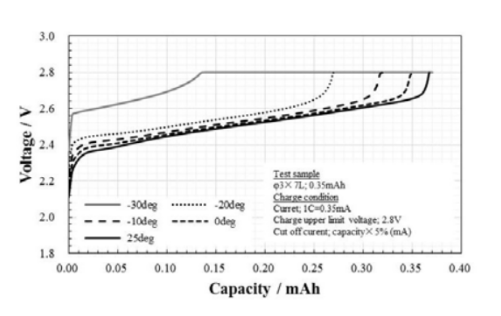

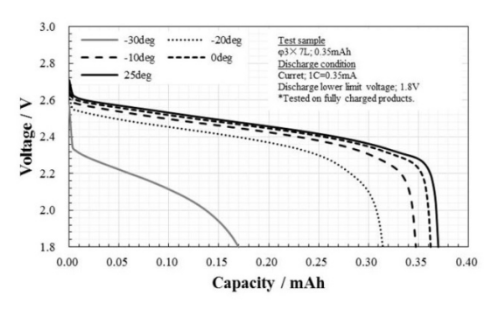

Discharging the SLB at low temperatures has the resistance between the electrode and electrolyte to increase requiring a higher voltage to initiate the discharge and the capacity to drop as a result. At ‐30 °C the charge capacity decreases to ~52% of the room temperature value and the discharge capacity drops to 46%. Li‐ion batteries have much higher resistances at low temperatures resulting in overcharge/ over discharge voltages. Thermal runaway can result causing rupturing and fire. To prevent this from occurring battery packs using thermistors to control low temperature operation are required for standard Li‐ion batteries where the SLB can be used without the use of temperature management systems. See figures 2 and 3 below.

Figure 2 – This chart shows the charging curves for the φ3x7L (mm) case size part at a current value of 1 C for different ambient temperatures.

Figure 3 ‐ This chart shows the discharging curves for the φ3x7L (mm) case size part at a current value of 1 C for different ambient temperatures.

The SLB is more resistant to overcharging the typical Li‐ion batteries. No significant degradation was observed during charge/ discharge cycle testing at voltages exceeding 2.8 V for the SLB. Even after 1,500 cycles where the 0.35 mAh SLB was charged to 3.3 V at a charging rate of 10 C and a discharge rate of 1 C to 1.8 V the battery retained 90% of its storage capacity.

The SLB has excellent over‐discharge resistance. The SLB can be discharged down to 0 V and stored up to 1,100 hours at various temperatures and they will not have any significant decline in storage capacity.

After the SLB series was discharged SLB 1800 times from 2.8 V to 0 V, the energy storage capacity decreased by only 30% at 60 °C and by 22% at 40 °C.

The SLB series electrical characteristics and its unique mounting make it superior when compared to EDLCs and other types of Li‐ion rechargeable batteries. Their case style allows them to be mounted onto circuit boards without any special fixturing and can be mounted using automated processes can reduce production costs and production time. The SLBs' electrical characteristics allow them to be used in applications where other energy storage devices do not have the performance or size required.